3D Printing Prototyping

Create and customize. Streamline and save. Break down design barriers and scale your business with RJCmold 3D printing services. Get instant online quotes on parts in over 80 metal and plastic materials. ISO 9001:2015, ISO 13485 and AS9100D certified.

Rapid Prototyping

Mold provide rapid prototyping services to help our customer to verify their design or market demonstration purpose prior to heavy investment on steel mold , through 3D printing and CNC machining, silicone molds, we can deliver prototypes part at low cost in short time.

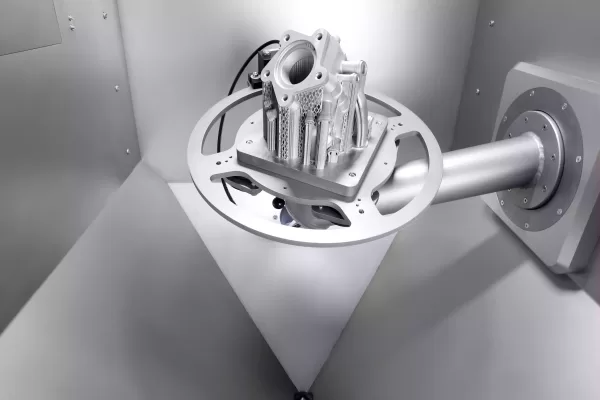

Advantages of 3D Printing

Building parts layer-by-layer brings about many benefits that open up design possibilities that were previously unachievable through traditional processes like injection molding, machining, or casting.

- Complex, organic geometries with limited impact on part cost

- Consolidation of multi-component assembly into a single part

- No upfront tooling costs

- Fast production for parts within 24 hours

- Internal features for advanced heat transfer and flow applications

Our 3D Printing Capabilities

SLA (Stereolithography)

High-resolution resin printing ideal for detailed appearance prototypes.

SLS (Selective Laser Sintering)

Strong, durable nylon parts perfect for functional testing and assembly.

MJF (Multi Jet Fusion)

Fast, scalable production of consistent nylon prototypes.

FDM

Cost-effective thermoplastic models for basic form and fit validation.

3D Printing General Tolerances & Design Guidelines

To ensure your designs are optimized for manufacturing, we have outlined general tolerances and design guidelines below. These recommendations will help you achieve the best possible results for your 3D printed parts.

Our 3D printing processes adhere to the following general tolerances unless otherwise specified. These tolerances apply to parts before secondary finishing or post-processing.

Description | Tolerance Notes |

Part Size | We can accommodate parts up to 500mm x 500mm x 500mm without splitting or bonding. |

Minimum Feature Size | Typical range: 0.5mm – 1.5mm (depending on material and technology). |

Minimum Wall Thickness | Typical range: 0.5mm – 1.0mm (may vary based on material and part geometry). |

Clearance Between Features | Recommended minimum: 0.5mm for moving parts or assemblies. |

Tips:For tighter tolerances or specific requirements, please contact our team for customized solutions.

Turn your ideas into prototypes faster. Contact us for a quote today!

Case Studies Of 3D Printing Prototyping Solutions

- Appearance verification models

- Functional testing prototypes

- Structural assembly validation

Advantages of prototyping and 3D printing

Prototyping and 3D printing offer key advantages that help businesses accelerate innovation and improve product quality.

Cost Efficiency

3D printing reduces tooling costs and minimizes the financial risk of early-stage product development, especially for small batches.

Experience

Years of working in the plastic mold sector have honed our ability to deliver high standard parts for diverse applications.

Design Excellence

Rapid prototyping significantly shortens the time from design to physical model, enabling quicker testing and iteration.

Efficiency

Rapid prototyping significantly shortens the time from design to physical model, enabling quicker testing and iteration.

Customer Review:

- Precision in size and dimensions

- Durable and flexible nylon material

- Ideal for intricate designs

- High-quality 3D printing results

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.